ເນື່ອງຈາກການພັດທະນາແລະຄວາມນິຍົມຂອງຍານພາຫະນະປະສົມແລະຍານພາຫະນະໄຟຟ້າ, ຄວາມຕ້ອງການສໍາລັບມໍເຕີຂັບລົດທີ່ປະຕິບັດໂດຍຍານພາຫະນະໄຟຟ້າຈະສືບຕໍ່ເພີ່ມຂຶ້ນໃນອະນາຄົດ. ເພື່ອຕອບສະໜອງຄວາມຕ້ອງການຂອງທົ່ວໂລກນີ້, ຫລາຍບໍລິສັດຍັງໄດ້ພັດທະນາຜະລິດຕະພັນສາຍໄຟທີ່ມີການເຊື່ອມຕໍ່ກັນແບບຮາບພຽງ.

ມໍເຕີໄຟຟ້າຖືກນໍາໃຊ້ຢ່າງກວ້າງຂວາງໃນອຸດສາຫະກໍາ, ມີລະດັບການຄຸ້ມຄອງພະລັງງານທີ່ກວ້າງຂວາງແລະຫຼາຍປະເພດ. ຢ່າງໃດກໍຕາມ, ເນື່ອງຈາກຄວາມຕ້ອງການທີ່ສູງຂຶ້ນຂອງຍານພາຫະນະພະລັງງານໃຫມ່ໃນມໍເຕີຂັບເຄື່ອນໃນດ້ານພະລັງງານ, ແຮງບິດ, ປະລິມານ, ຄຸນນະພາບ, ການລະບາຍຄວາມຮ້ອນ, ແລະອື່ນໆ, ເມື່ອປຽບທຽບກັບມໍເຕີອຸດສາຫະກໍາ, ຍານພາຫະນະພະລັງງານໃຫມ່ຕ້ອງມີການປະຕິບັດທີ່ດີກວ່າ, ເຊັ່ນ: ຂະຫນາດຂະຫນາດນ້ອຍເພື່ອປັບຕົວກັບພື້ນທີ່ພາຍໃນຂອງຍານພາຫະນະທີ່ຈໍາກັດ, ລະດັບອຸນຫະພູມການເຮັດວຽກກວ້າງ (-40 ~ 1050C), ການປັບຕົວກັບສະພາບແວດລ້ອມການເຮັດວຽກທີ່ບໍ່ຫມັ້ນຄົງ, ຄວາມປອດໄພຂອງຍານພາຫະນະສູງ, ຄວາມຫນ້າເຊື່ອຖືສູງ. ປະສິດທິພາບການເລັ່ງ (1.0-1.5kW/kg), ດັ່ງນັ້ນມີ motors ຂັບຂ້ອນຂ້າງຫນ້ອຍ, ແລະການຄຸ້ມຄອງພະລັງງານແມ່ນຂ້ອນຂ້າງແຄບ, ສົ່ງຜົນໃຫ້ຜະລິດຕະພັນທີ່ຂ້ອນຂ້າງເຂັ້ມຂຸ້ນ.

ເປັນຫຍັງເທັກໂນໂລຍີ “ສາຍແປ” ຈຶ່ງເປັນທ່າອ່ຽງທີ່ຫຼີກລ່ຽງບໍ່ໄດ້? ເຫດຜົນທີ່ສໍາຄັນອັນຫນຶ່ງແມ່ນວ່ານະໂຍບາຍຮຽກຮ້ອງໃຫ້ມີຄວາມຫນາແຫນ້ນຂອງພະລັງງານເພີ່ມຂຶ້ນຢ່າງຫຼວງຫຼາຍຂອງມໍເຕີຂັບລົດ. ຕາມທັດສະນະນະໂຍບາຍ, ແຜນການ 5 ປີຄັ້ງທີ 13 ສະເໜີວ່າ ຄວາມໜາແໜ້ນຂອງພະລັງງານສູງສຸດຂອງເຄື່ອງຈັກຂັບເຄື່ອນລົດພະລັງງານໃໝ່ຄວນບັນລຸ 4kw/kg, ເຊິ່ງຢູ່ໃນລະດັບຜະລິດຕະພັນ. ຈາກທັດສະນະຂອງອຸດສາຫະກໍາທັງຫມົດ, ລະດັບຜະລິດຕະພັນໃນປະຈຸບັນຂອງຈີນແມ່ນຢູ່ລະຫວ່າງ 3.2-3.3kW / ກິໂລ, ສະນັ້ນຍັງມີ 30% ຊ່ອງສໍາລັບການປັບປຸງ.

ເພື່ອບັນລຸຄວາມຫນາແຫນ້ນຂອງພະລັງງານເພີ່ມຂຶ້ນ, ມັນຈໍາເປັນຕ້ອງໄດ້ຮັບຮອງເອົາເຕັກໂນໂລຢີ "ມໍເຕີສາຍແປ", ຊຶ່ງຫມາຍຄວາມວ່າອຸດສາຫະກໍາໄດ້ເປັນເອກະສັນກັນກ່ຽວກັບແນວໂນ້ມຂອງ "ມໍເຕີສາຍແປ". ເຫດຜົນພື້ນຖານແມ່ນຍັງເປັນທ່າແຮງອັນໃຫຍ່ຫຼວງຂອງເຕັກໂນໂລຢີສາຍແບນ.

ບໍລິສັດລົດຍົນຕ່າງປະເທດທີ່ມີຊື່ສຽງໄດ້ໃຊ້ສາຍຮາບພຽງຢູ່ໃນມໍເຕີຂັບຂອງພວກເຂົາ. ຕົວຢ່າງ:

· ໃນປີ 2007, Chevrolet VOLT ໄດ້ຮັບຮອງເອົາເຕັກໂນໂລຊີຂອງ Hair Pin (hairpin flat wire motor), ກັບຜູ້ສະຫນອງ Remy (ໄດ້ມາໂດຍອົງປະກອບຍັກໃຫຍ່ Borg Warner ໃນ 2015).

· ໃນປີ 2013, Nissan ໄດ້ນໍາໃຊ້ມໍເຕີສາຍຮາບພຽງຢູ່ໃນຍານພາຫະນະໄຟຟ້າ, ກັບຜູ້ສະຫນອງໃຫ້ HITACHI.

· ໃນປີ 2015, Toyota ໄດ້ປ່ອຍ Prius ລຸ້ນທີ 4 ໂດຍໃຊ້ມໍເຕີສາຍແບນຈາກ Denso (ອຸປະກອນໄຟຟ້າຍີ່ປຸ່ນ).

ໃນປັດຈຸບັນ, ຮູບຮ່າງຂອງເສັ້ນຜ່າກາງຂອງສາຍ enameled ສ່ວນໃຫຍ່ແມ່ນເປັນວົງ, ແຕ່ສາຍ enameled ວົງມີຂໍ້ເສຍຂອງອັດຕາການຕື່ມຊ່ອງຕ່ໍາຫຼັງຈາກ winding, ເຊິ່ງຈໍາກັດຢ່າງຫຼວງຫຼາຍປະສິດທິພາບຂອງອົງປະກອບໄຟຟ້າທີ່ສອດຄ້ອງກັນ. ໂດຍທົ່ວໄປແລ້ວ, ຫຼັງຈາກການໂຫຼດເຕັມ winding, ອັດຕາການຕື່ມ slot ຂອງສາຍ enameled ແມ່ນປະມານ 78%. ດັ່ງນັ້ນ, ມັນເປັນການຍາກທີ່ຈະຕອບສະຫນອງຄວາມຕ້ອງການຂອງການພັດທະນາເຕັກໂນໂລຢີສໍາລັບແບນ, ນ້ໍາຫນັກເບົາ, ພະລັງງານຕ່ໍາ, ແລະອົງປະກອບທີ່ມີປະສິດທິພາບສູງ. ດ້ວຍວິວັດທະນາການຂອງເທັກໂນໂລຍີ, ສາຍໄຟ enameled ຮາບພຽງໄດ້ເກີດຂື້ນ.

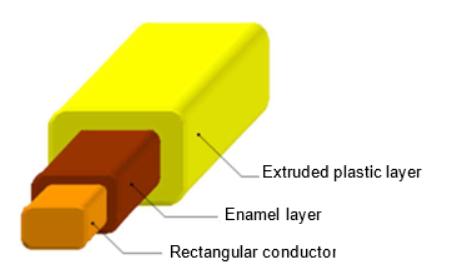

ລວດ enameled ແປແມ່ນປະເພດຂອງສາຍ enameled, ເປັນສາຍ winding ເຮັດດ້ວຍທອງແດງທີ່ບໍ່ມີອົກຊີເຈນຫຼື rods ອາລູມິນຽມໄຟຟ້າທີ່ຖືກດຶງ, extruded, ຫຼືມ້ວນໂດຍສະເພາະໃດຫນຶ່ງຂອງ mold, ແລະຫຼັງຈາກນັ້ນເຄືອບດ້ວຍສີ insulation ຫຼາຍຄັ້ງ. ຄວາມຫນາຕັ້ງແຕ່ 0.025mm ຫາ 2mm, ແລະຄວາມກວ້າງໂດຍທົ່ວໄປແມ່ນຫນ້ອຍກວ່າ 5mm, ມີອັດຕາສ່ວນຄວາມກວ້າງກັບຄວາມຫນາຕັ້ງແຕ່ 2: 1 ຫາ 50: 1.

ສາຍ enameled ແປໄດ້ຖືກນໍາໃຊ້ຢ່າງກວ້າງຂວາງ, ໂດຍສະເພາະໃນ windings ຂອງອຸປະກອນໄຟຟ້າຕ່າງໆເຊັ່ນ: ອຸປະກອນໂທລະຄົມນາຄົມ, ຫມໍ້ແປງ, ມໍເຕີ, ແລະເຄື່ອງກໍາເນີດໄຟຟ້າ.

ເວລາປະກາດ: 17-05-2023